Exploring the seamless integration of Altium Auto Route into Automotive PCB Design, this introduction captivates readers with a comprehensive overview of how this tool revolutionizes the design process.

Highlighting the key features and benefits, this paragraph sets the stage for a deep dive into the world of automotive PCB design with Altium Auto Route.

Introduction to Altium Auto Route Integration in Automotive PCB Design

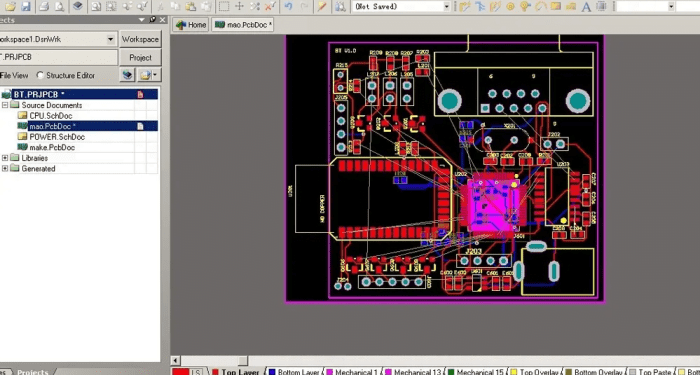

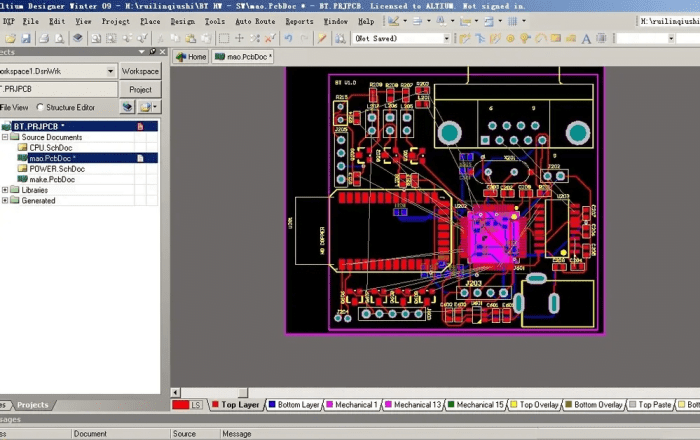

Altium Auto Route is a powerful feature that automates the routing of tracks on a PCB design, saving time and effort in the design process. In the context of automotive PCB design, Altium Auto Route plays a crucial role in ensuring the efficiency and accuracy of the layout.

Significance of Altium Auto Route in Automotive PCB Design

Altium Auto Route streamlines the PCB design process for automotive applications by automatically routing connections between components based on specified design rules. This automation helps in reducing design time and minimizing the risk of errors, especially in complex automotive electronic systems.

Benefits of Altium Auto Route for Automotive PCB Design

- Efficiency: Altium Auto Route accelerates the routing process, allowing designers to focus on other aspects of the design.

- Accuracy: By following predefined design rules, Altium Auto Route ensures that connections are routed correctly, reducing the likelihood of signal interference or short circuits.

- Flexibility: Designers can easily customize routing preferences and constraints to meet specific requirements of automotive PCB designs.

- Consistency: Altium Auto Route maintains a consistent routing style throughout the PCB layout, enhancing the overall design quality.

Key Features of Altium Auto Route for Automotive PCB Design

Altium Auto Route offers a range of key features specifically designed to meet the requirements of automotive PCB design. These features contribute to achieving optimal routing solutions and enhancing efficiency in the design process.

Automation Capabilities

Altium Auto Route provides automation capabilities that streamline the routing process for automotive PCBs. By automating the routing tasks, designers can save time and effort while ensuring accuracy and consistency in the design. This feature allows for quick iterations and adjustments, leading to faster design completion and improved productivity.

Intelligent Routing Algorithms

Altium Auto Route is equipped with intelligent routing algorithms that analyze the design requirements and constraints to generate efficient routing solutions for automotive PCBs. These algorithms optimize the routing paths based on signal integrity, power distribution, and other critical factors, resulting in high-quality designs that meet industry standards.

Interactive Routing Tools

The interactive routing tools in Altium Auto Route enable designers to manually adjust and fine-tune the routing paths as needed. This feature allows for greater control over the routing process, ensuring that designers can implement specific design requirements and address any design challenges effectively.

By combining automation with manual intervention, designers can achieve the desired balance between efficiency and customization in automotive PCB design.

Integration of Altium Auto Route with Automotive Design Constraints

Altium Auto Route seamlessly integrates with automotive design constraints to ensure optimal performance and reliability in PCB designs for automotive applications. Let's explore how Altium Auto Route addresses key considerations such as EMI/EMC requirements and high-speed signal integrity challenges specific to automotive PCBs.

EMI/EMC Requirements

- Altium Auto Route offers advanced routing algorithms that prioritize EMI/EMC compliance by minimizing signal interference and crosstalk.

- The software provides tools for impedance control, signal shielding, and ground plane design to mitigate electromagnetic interference in automotive PCB layouts.

- Altium Auto Route allows users to set specific design rules and constraints to meet EMI/EMC standards mandated for automotive electronics applications.

High-Speed Signal Integrity Challenges

- Altium Auto Route employs intelligent routing techniques to manage high-speed signal paths effectively, reducing signal distortions and reflections in automotive PCB designs.

- The software enables differential pair routing, length matching, and controlled impedance routing to maintain signal integrity for critical automotive electronics interfaces.

- Altium Auto Route includes features like signal via stitching and signal integrity analysis tools to optimize signal performance and reliability in high-speed automotive applications.

Adaptation to Automotive-Specific Layout Considerations

- Altium Auto Route accommodates automotive-specific layout considerations such as compact design requirements, thermal management constraints, and rugged environmental conditions.

- The software allows for flexible placement of components, optimized routing paths, and efficient use of PCB real estate to meet the unique challenges of automotive PCB design.

- Altium Auto Route supports multi-layer PCB configurations, controlled impedance routing, and thermal vias to address thermal dissipation and mechanical robustness requirements in automotive electronic systems.

Best Practices for Utilizing Altium Auto Route in Automotive PCB Design

When working on automotive PCB design projects using Altium Auto Route, it is essential to follow best practices to optimize your workflow and avoid common pitfalls. By incorporating the following tips into your design process, you can ensure a smooth and efficient integration of Altium Auto Route into your automotive PCB projects.

Optimizing Altium Auto Route Usage

- Utilize design rules: Define clear design rules and constraints before running the auto-routing feature to ensure that the routing meets the required specifications.

- Segmentation: Break down the routing into smaller segments to allow for better control and optimization of the routing paths.

- Use interactive routing: Combine auto-routing with manual routing to achieve the best results, especially for critical signal paths.

Common Pitfalls to Avoid

- Over-reliance on auto-routing: While Altium Auto Route can automate the routing process, it is crucial to review and validate the results to ensure signal integrity and compliance with design rules.

- Ignoring design constraints: Failing to set up proper design constraints can lead to routing errors and signal integrity issues in the final PCB layout.

- Not optimizing routing paths: Avoid unnecessary sharp angles, long trace lengths, or crowded routing paths that can impact signal performance and manufacturability.

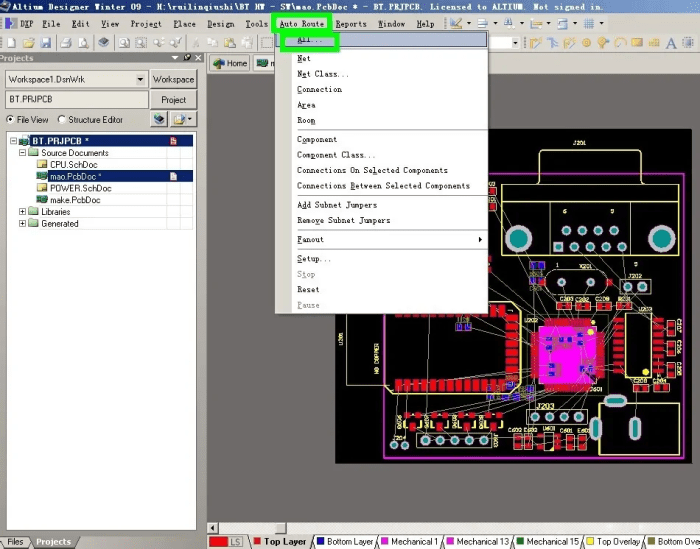

Step-by-Step Guide for Effective Integration

- Set up design rules: Define electrical constraints, routing widths, and other parameters to guide the auto-routing process.

- Pre-route planning: Analyze the PCB layout and identify critical signal paths that require manual routing or specific constraints.

- Run auto-routing: Execute the auto-routing feature while considering segmentation and interaction with manual routing for optimal results.

- Review and validate: Inspect the routed paths, check for design rule violations, and ensure signal integrity before finalizing the PCB layout.

End of Discussion

In conclusion, the discussion surrounding Altium Auto Route's integration into automotive PCB design showcases its adaptability, efficiency, and effectiveness in meeting design constraints.

Question & Answer Hub

How does Altium Auto Route handle high-speed signal integrity challenges in automotive PCBs?

Altium Auto Route utilizes advanced algorithms and design rules to ensure signal integrity is maintained, even in high-speed environments.

What are some common pitfalls to avoid when using Altium Auto Route in automotive PCB design?

Common pitfalls include overlooking design constraints, improper layer stackup configurations, and not utilizing the automation features effectively.

Can Altium Auto Route adapt to unique layout considerations specific to automotive PCBs?

Yes, Altium Auto Route can adapt to automotive-specific layout considerations by allowing customization and optimization based on the design requirements.